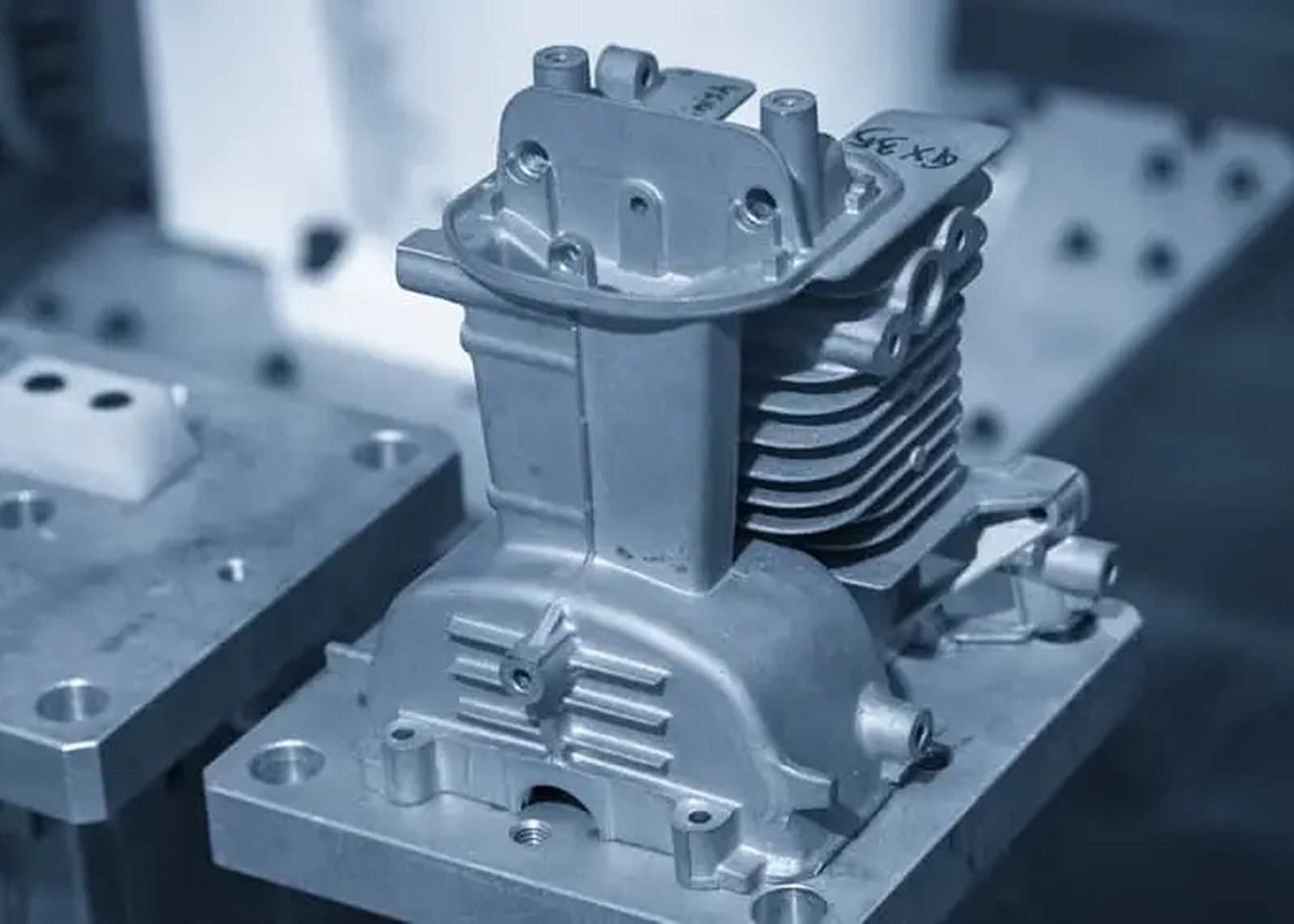

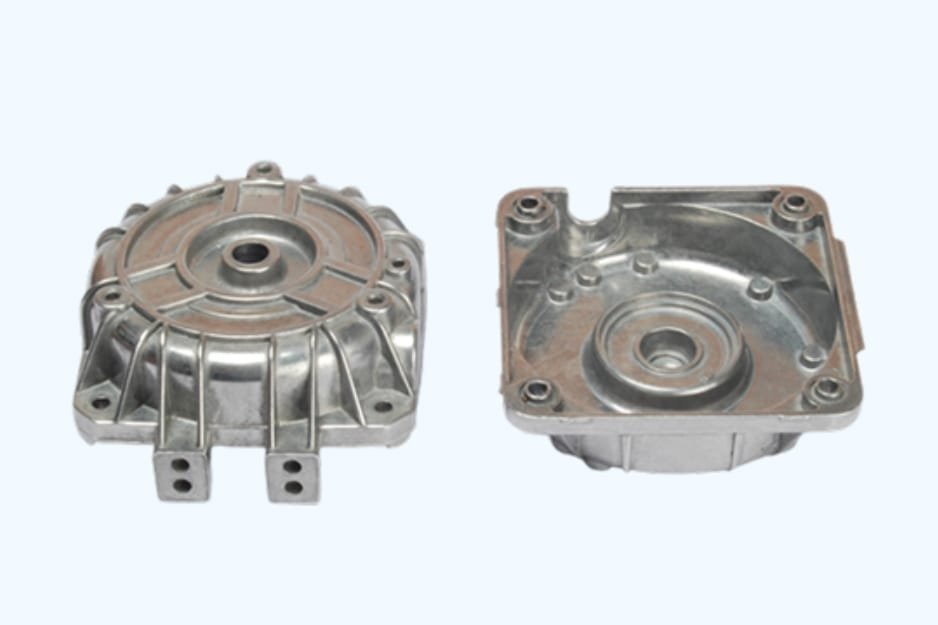

Oerigo Global offers custom die casting, sand casting, gravity casting, and investment casting services. We specialize in aluminum, steel, iron, brass, and specialty alloys—delivering precision components for automotive, industrial, and consumer applications.

With advanced tool design and specialized casting equipment, we support both prototype development and high-volume production. Our solutions are tailored to your exact specifications, ensuring consistent quality and fast turnaround.

From prototype castings to full-scale production, Oerigo Global delivers custom metal casting solutions tailored to your exact specifications. We support rapid development cycles, small and large batch casting, and a wide range of materials including aluminum, steel, iron, and brass.

Quality is at the core of Oerigo’s manufacturing processes. Be it systems, people, processes or technology, everything moves in one gear to deliver 100% certified quality for every project and every customer.